Search

Search

APIs are the premise for the production of pharmaceutical preparations. In each link of the pharmaceutical industry chain, they play a role in the processing and manufacturing of basic pharmaceutical industry raw materials, and most of them are outsourced. The production process of APIs includes chemical synthesis, fermentation, animal and plant extraction, etc. According to the source of acquisition, APIs are generally divided into chemically synthesized APIs, APIs extracted from animals and plants, and APIs obtained from production fermentation and cell culture; APIs are also classified into non-sterile APIs according to the microbial level and target dosage form of the product. and sterile APIs. A typical API production process is as follows.

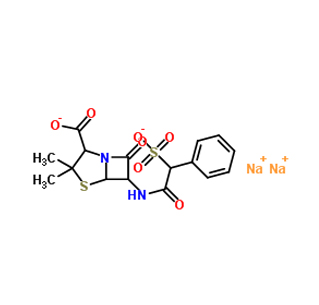

Chemical synthesis of APIs refers to the production method of APIs in which various chemical raw materials are chemically reacted under certain conditions to obtain products with certain efficacy, and then through crystallization, drying and other processes to make them reach various indicators of drugs.

Fermentation is also one of the important methods for the production of APIs, especially antibiotic APIs, such as penicillins, cephalosporins, etc., which are usually obtained by a semi-synthetic method combining fermentation and chemical synthesis. First, the main structure of the target compound is obtained through biological fermentation, such as the specific 3-lactam structure of penicillin, and then the structure is modified to obtain the final target compound; finally, the final API product is obtained through refining and recrystallization.

Similar to sterile preparations, sterile APIs are also divided into terminally sterilized sterile APIs and non-terminally sterilized sterile APIs. However, because most APIs are sensitive to high temperature, high heat, high humidity, high pressure, radiation, etc. Terminally sterilized sterile APIs are rare. At present, sterile APIs that are not terminally sterilized usually combine the final product refining or salt formation with the sterilization process, and use pre-filtration and two-stage sterilization filtration to achieve the sterility of the final product. The feed liquid after sterilization filtration is usually crystallized, freeze-dried or spray-dried to obtain the final sterile bulk drug product.

Compared with non-sterile APIs, the production of sterile APIs not only needs to pay attention to the requirements of chemical quality indicators such as product impurities and physical and chemical properties, but also needs to pay attention to the sterility assurance of products from the beginning of process design. Therefore, the production of sterile APIs has higher requirements on the environment and equipment.

Nature is a treasure trove of natural compounds. Animals or plants produce many compounds that cannot be synthesized at present but are of great significance to the treatment of diseases through their own metabolism. Therefore, animal and plant extraction is an important way to obtain target compounds and one of the main ways to produce APIs.

The drug outsourcing process services provided by many pharmaceutical R&D companies ensure that the processes operating within the predetermined process parameters can continuously and effectively produce drugs that meet the predetermined specifications and quality. In the process of R&D and production of APIs, the main drug production quality management is also required. The quality management standard of pharmaceutical production is based on production, and there is quality in production. The quality of medicines is produced, not tested, and production management should be carried out in accordance with GMP. This includes the sourcing of vitamin raw material suppliers, amino api, and China api terbinafine hydrochloride,hydroxypropyl-beta-cyclodextrin bulk.

Other Blogs about Active Pharmaceutical Ingredients API:

Quick Links

Add:

E-mail:

English

English  Español

Español  français

français  العربية

العربية