Search

Search

Vitamins play a vital role in supporting our overall health and well-being. Behind every vitamin supplement lies a complex journey from nature to nutrition, where raw materials undergo meticulous processes to become essential nutrients. In this blog, we will delve into the journey of raw materials in vitamin production, exploring their sourcing, extraction, processing, and transformation into the supplements that nourish our bodies.

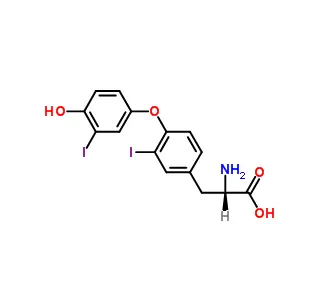

Raw materials for vitamin production are sourced from various natural sources across the globe. Whether it's plants, fruits, vegetables, or microorganisms, the selection of high-quality raw materials is essential to ensure the potency and effectiveness of the vitamins. We will explore the diverse sources of raw materials, the factors considered during their selection, and the sustainable practices implemented to maintain ecological balance.

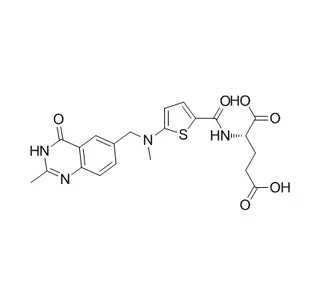

Once the raw materials are sourced, they undergo extraction processes to isolate the active vitamin compounds. Different techniques such as cold-pressing, solvent extraction, or fermentation may be employed depending on the nature of the raw material. We will delve into these extraction methods, highlighting their significance in obtaining concentrated vitamin forms while preserving their integrity and nutritional value.

Raw materials and extracted vitamin compounds undergo rigorous quality control and testing procedures to ensure safety and potency. These tests verify the identity, purity, and strength of the raw materials, ruling out any potential contaminants or deviations from desired specifications. We will explore the quality control measures implemented by manufacturers to maintain the highest standards in vitamin production.

After quality control, the extracted vitamin compounds are processed and formulated into various supplement formats such as tablets, capsules, liquids, or powders. Manufacturing processes, including blending, granulation, encapsulation, and tablet compression, ensure uniform distribution and dosage accuracy. We will dive into these manufacturing techniques, shedding light on the complex processes that transform raw materials into convenient and easily consumable vitamin supplements.

The bioavailability of vitamins, or the extent to which our bodies can absorb and utilize them, is influenced by the raw materials used. Factors such as formulation, combination with other nutrients, and the presence of absorption enhancers play a crucial role in maximizing bioavailability. We will explore how manufacturers optimize raw material selection and formulation strategies to enhance the bioavailability and efficacy of vitamin supplements.

Quick Links

Add:

E-mail:

English

English  Español

Español  français

français  العربية

العربية